Continental is driving forward the future of mobility, making it safer, cleaner and more convenient.

For more than 150 years Continental has been revolutionizing the way we move. Today, the industry is being shaped by forward-looking technologies such as automated and autonomous driving, smart infotainment and holistic connectivity, but also fundamental trends such as digitalization, sustainability and cost saving, which are just as much a part of the future of mobility as efficient safety technologies and driving comfort.

Autonomous and intelligent solutions connected to the cloud

Continental has expanded its portfolio for assisted and partially automated driving with the system-on-chip family from Ambarella, which enables faster processing of increased sensor data in the vehicle and paves the way for autonomous mobility. This helps ensure higher levels of environmental perception and therefore safer mobility. By reducing energy consumption and battery weight, the chip set can also increase the range of electric vehicles. It complements Continental’s solutions for assisted driving and further promotes vehicle automation.

Milestone in the development of future brake systems

Continental has introduced a new technology with its first customer, changing from a wet to a semi-dry brake system. The Future Brake System, which includes several new components, uses “dry” electromechanical brakes on the rear axle that do not require brake fluid. The brakes on the front axle continue to operate hydraulically. The new technology also includes the MK C2, a second-generation brake-by-wire system. The start of production at a North American car manufacturer is planned for 2025.

Program to increase R&D efficiency in the Automotive group sector

Continental launched the Automotive R&D Excellence Program in 2022, a strategic initiative to improve the competitiveness of product development within the Automotive group sector and ensure business success. Its goal is to create an organization that is able to adapt quickly to market needs, utilize state-of-the-art processes, methodologies and tools, identify effective business priorities and implement structured business solutions. Due to its holistic approach, the program consists of over 100 representatives and experts from all Automotive business areas, divided into nine work packages and three work streams.

Continental tires with polyester made from recycled PET bottles available throughout Europe since the summer

Continental tires containing polyester from recycled PET bottles have been available in Europe since June 2022. ContiRe.Tex technology can completely replace the polyester conventionally used in tire casings. It was first unveiled by Continental less than one year earlier in September 2021 and is the first technology of its kind to be used in tire production. Three tire lines featuring polyester from recycled PET bottles are currently on offer, each available in five sizes: the PremiumContact 6, the EcoContact 6 and the AllSeasonContact.

The specially developed technology uses polyester yarn obtained from used PET bottles that would not otherwise be recycled, without requiring any intermediate chemical steps. The bottles used come exclusively from regions without a closed recycling loop. Around 40 recycled PET bottles are used for each set of standardsize passenger car tires. This sustainable technology is much more efficient than other known methods for processing PET bottles into high-performance polyester yarns. By using recycled polyester yarn, Continental is taking a further step toward circular economies across product lines. Tires manufactured with ContiRe.Tex technology have a “Contains Recycled Material” logo on the sidewall.

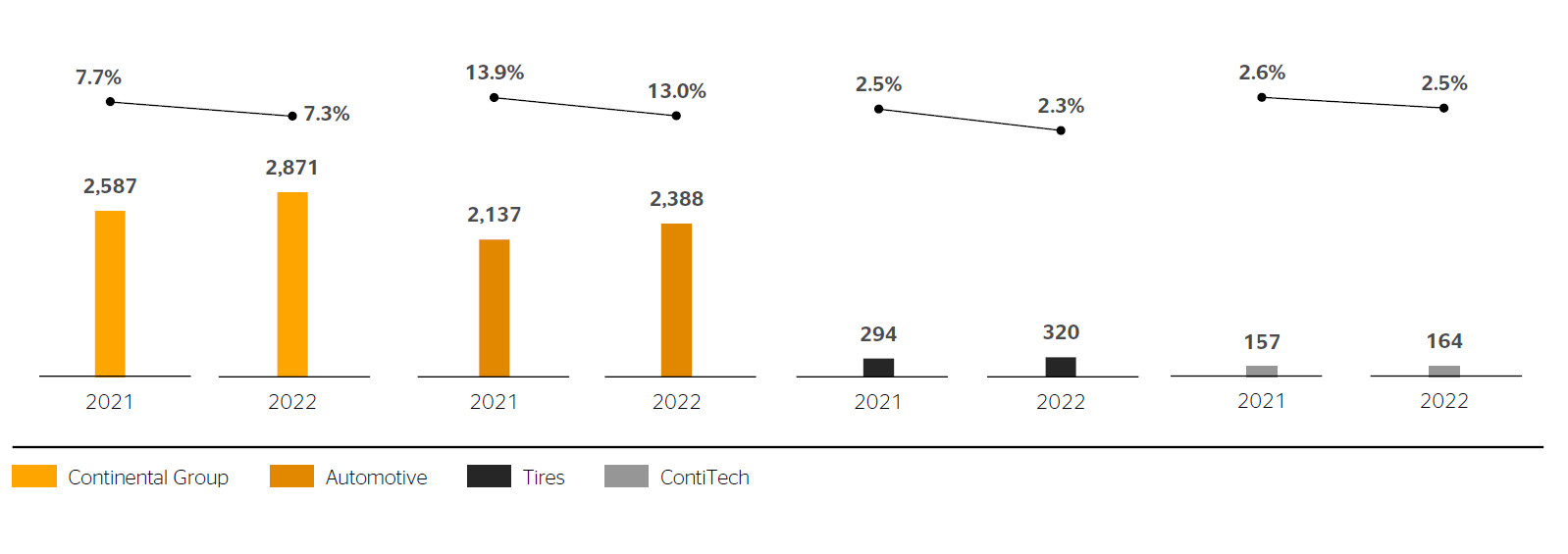

| Research and development expenses (net) | ||||

|---|---|---|---|---|

| 2022 | 2021 | |||

| € millions | % of sales | € millions | % of sales | |

| Automotive | 2,387.7 | 13.0 | 2,136.6 | 13.9 |

| Tires | 319.8 | 2.3 | 293.8 | 2.5 |

| ContiTech | 163.8 | 2.5 | 156.5 | 2.6 |

| Contract Manufacturing | 0.1 | 0.0 | -0.1 | 0.0 |

| Continental Group | 2,871.4 | 7.3 | 2,586.8 | 7.7 |

| Capitalization of research and development expenses | 24.4 | 31.5 | ||

| in % of research and development expenses | 0.8 | 1.2 | ||

| Depreciation on research and development expenses | 46.4 | 44.0 | ||

ContiConnect 2.0: digital tire management of the future

Continental has launched a comprehensive enhancement of its ContiConnect system that combines intelligent tire management with digital, service-based tire solutions. With ContiConnect 2.0, tires for passenger cars, trucks, buses and off-road vehicles can be serviced exactly when needed. In addition to the previous functions such as continuous tire pressure monitoring, the newly developed version also allows fleet customers to digitally track the remaining mileage, tread depth and condition of all tires in their fleets. The coordination of vehicle and tire services generates cost efficiency, lowers emissions and strengthens sustainability. In the off-road vehicle sector, ContiConnect is already used frequently by fleet customers in construction, intralogistics and at ports.

Three new tire solutions for sustainable passenger and goods transport over short and long distances

At the IAA Transportation 2022 in Hanover, Continental presented a range of innovative tire solutions aimed at improving the sustainability of passenger and goods transport over short and long distances. The Conti Urban, for example, is a concept tire specially designed for electric buses and delivery vehicles of the future. The prototype, which has already been approved for road use and could soon go into a trial phase with customers, consists of nearly 50 percent renewable and recycled materials. After a single retreading, this figure rises to more than 90 percent. Furthermore, the concept tire’s noise level has been specially optimized. Continental believes that greater sustainability is essential for urban buses and delivery vehicles. In particular, as the demand for innercity passenger and freight transport is constantly growing, more and more electrified city buses are being registered too.

CONTI LoadSense: powerful load monitoring system for conveyor belts

With CONTI LoadSense, a newly developed monitoring system, Continental is expanding its portfolio for predictive maintenance and status monitoring for conveyor systems. Customers can track all aspects of their installations’ carrying capacity thanks to the system’s reliable data. The Continental system uses radar and ultrasonic sensors to monitor the material flow on the conveyor belt around the clock. It scans the material and the belt from different angles to determine the position of the load and belt. The data is then correlated to calculate the volume flow and determine potential material losses. Because standardized limits (CEMA, DIN and ISO standards) are automatically incorporated into the system software, the customer can rely on the safe and efficient operation of the conveyor system and digitally track process performance in real time. System alarms automatically report when critical process conditions are detected. CONTI LoadSense can be retrofitted to conveyor systems and is suitable for all conveyor belts.