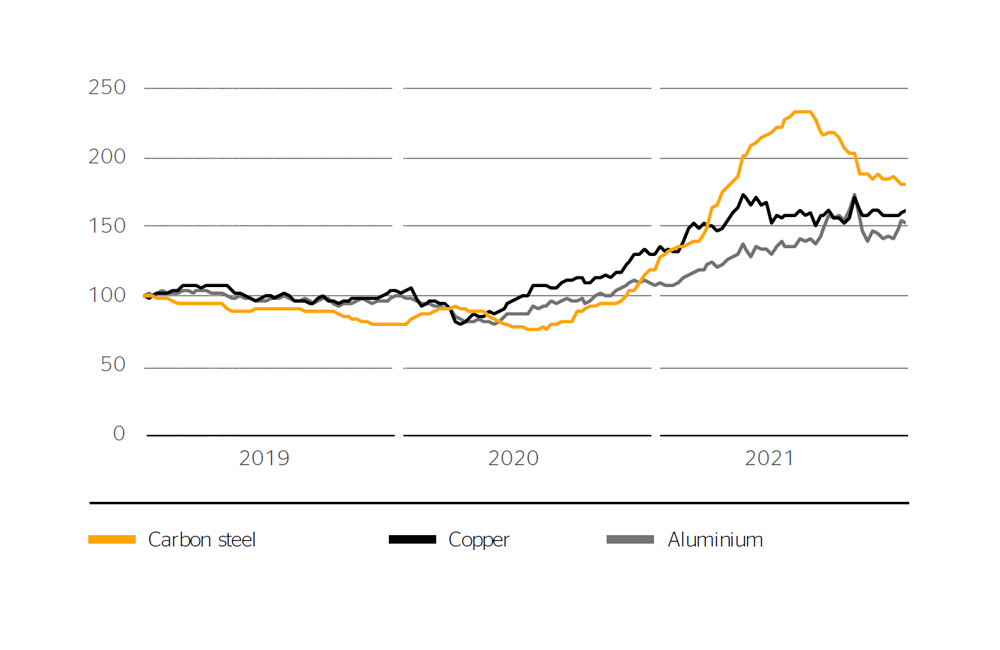

Carbon steel and stainless steel are input materials for many of the mechanical components such as die-cast parts integrated by Continental into its products. Steel wire is used in particular in tire production as steel cord but also, for example, in conveyor belts and timing belts to increase tensile strength. Aluminum is used in particular for die-cast parts and stamped and bent components, while copper is used in particular in electric motors, mechatronic components and printed circuit boards. On a euro basis, prices for carbon steel rose by more than 50% on average in 2021. For some materials such as hot-rolled coil, they more than doubled. Prices for aluminum and copper, which had already increased in the previous year, rose even further in the year under review. The annual average price of aluminum increased by around 44% on a US dollar basis in 2021, while that of copper rose by around 50% on a US dollar basis.

Precious metals such as silver and gold are used by Continental and by our suppliers to coat components. The average price of silver was up 22% year-on-year on a US dollar basis in 2021. In contrast to this, following the rise in the previous year, the price of gold remained relatively stable with an increase of 2%.

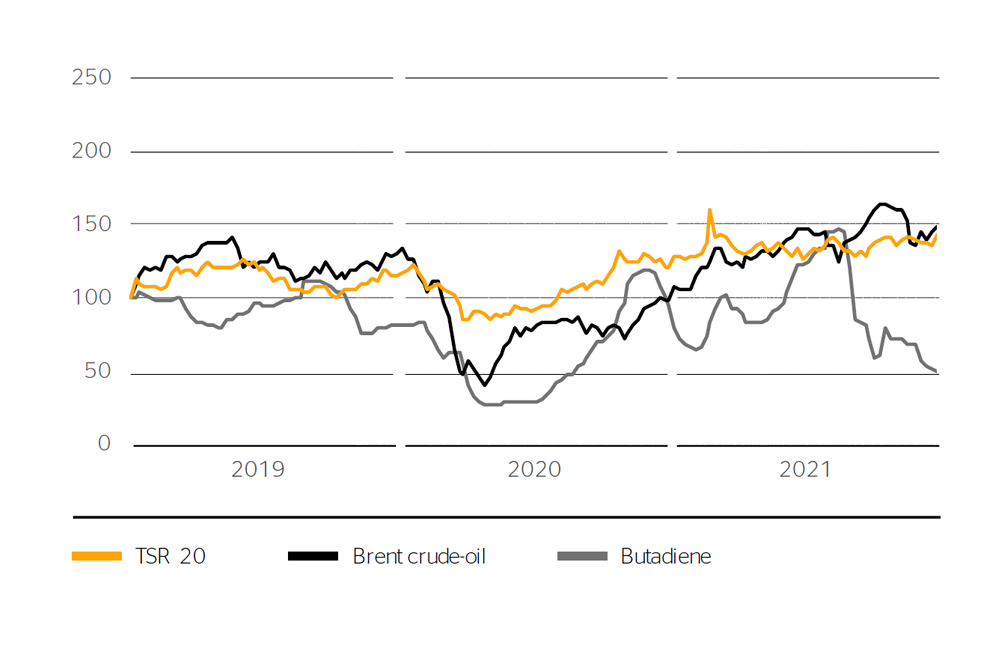

Renewed demand for tires led to a rise in prices for natural rubber in the year under review. The average price of natural rubber TSR 20 was up 27% year-on-year on a US dollar basis, for example.

Crude oil is the most important basic building block for syntheticrubber input materials such as butadiene and styrene as well as for carbon black, various other chemicals, and plastics. The price of crude oil continued the upward trend seen in the second half of the previous year in 2021. Due to rising demand and only an incremental increase in production levels, the annual average price of Brent crude oil increased by 66% year-on-year on a US dollar basis.

The rise in the price of crude oil as well as increasing demand led to significant price increases for various input materials for synthetic rubber in 2021. Annual average prices for butadiene and styrene, for example, increased by 46% and 58%, respectively, on a US dollar basis.

Various plastic granules, known as resins, also saw a noticeable increase in 2021 as a result of the rise in the price of crude oil. Resins, as technical thermoplastics, are required by Continental and our suppliers, in particular for the manufacture of housing parts in the Automotive Technologies group sector and various other plastic parts in the ContiTech business area. On a US dollar basis, prices for resins rose by around 50% on average in 2021.

TSR 20, crude oil and butadiene

Indexed to January 1, 2019

Sources:

TSR 20: rolling one-month contracts from the Singapore Exchange (US $ cents per kg).

Crude oil: European Brent spot price from Bloomberg (US $ per barrel).

Butadiene: South Korea spot price (FOB) from PolymerUpdate.com (US $ per metric ton).

Continental uses natural and synthetic rubber in large quantities for the manufacture of tires and industrial rubber products. It also uses relatively large quantities of carbon black as a filler material and of steel cord and nylon cord as structural materials. Due to the high volumes and direct purchasing of raw materials, their price development has a significant influence on the earnings of the Rubber Technologies group sector, particularly the Tires business area.

Overall, despite a slightly stronger euro, the described price developments for raw materials led to significant cost burdens in all group sectors in 2021, but in particular Rubber Technologies.

There is usually a gap of several months between purchasing raw materials, their delivery and their use in production, depending on the product and contractual arrangement. As a result, the rise in spot prices in the second half of 2021 is also expected to lead to increased costs for raw materials in fiscal 2022.