Continental is developing the new horsepower for the mobility of the future.

Continental is leading the way with its technology solutions for the new era of mobility. These range from innovative, high-performance computers and solutions for the rapid, cost-efficient implementation of digital mobility to sustainable vehicle interiors of the future and environmentally friendly tires that enhance energy efficiency when driving. Continental’s technology portfolio extends from the road to the cloud. The shift from hardware-based mechatronic products to more software-driven solutions is well underway, and we are helping to shape this new era with our proven expertise in software-driven mobility. A large number of new cars worldwide are already fitted with hardware and software solutions from Continental – ensuring safety, convenience and sustainability.

Continental and Aurora partnership for commercially scalable autonomous trucking systems

The technology companies Continental and Aurora entered into an exclusive partnership in April 2023. Together, they will deliver the first commercially scalable generation of Aurora’s integrated hardware and software system – the Aurora Driver – in the USA. The SAE (Society of Automotive Engineers) Level 4 system will be available to carriers and commercial fleet operators across the USA to help reduce costs to facilitate broader adoption. Production is set to commence in 2027.

In order to industrialize the Aurora Driver, Continental will bring its decades of experience in the field of system development for safe and reliable vehicle solutions to the partnership. Continental will contribute not only the entire hardware system, but also a new fallback system. This ensures, in the unlikely event of a malfunction of the autonomous primary system, that the driverless truck’s fallback system will safely take over and safely drive to the nearest safe location. In addition, Continental will take care of the entire life cycle of the supplied autonomous hardware solutions for the Aurora Driver, from the production line all the way through to decommissioning.

Continental and Google Cloud equip cars with generative artificial intelligence (AI)

Continental announced a partnership with Google Cloud at IAA Mobility in September 2023. Together, the two companies will equip cars with artificial intelligence (AI), making Continental one of the first automotive suppliers to integrate Google Cloud capabilities directly into vehicle computers – allowing drivers quite literally to “talk” with their vehicles. No matter if drivers, for example, need helping find the right tire pressure when the car is fully loaded or want to know more about local places of interest at their destination or along their route, the generative AI gathers the required information and answers the driver’s questions. The two companies each bring their respective expertise to the partnership, namely in automotive, software, artificial intelligence and cloud computing.

With this technology, Continental is offering yet another building block from the road to the cloud and expanding the instrumentation, entertainment and driver assistance functions already integrated into its high-performance computer for smart cockpits (Smart Cockpit HPC). This, in turn, cuts the development time and effort, complexity and cost for automotive manufacturers. The Smart Cockpit HPC combines user experience and system performance, while meeting customer requirements for typical cockpit designs featuring driver and center displays. The pre-integrated functionality reduces costs, which ultimately results in fast time to market – from order to start of production in just 18 months.

Continental and Synopsys accelerate software development

Continental and Synopsys are accelerating the development and validation of software features and applications for the software-defined vehicle. The companies have teamed up to develop advanced virtual prototyping solutions for virtual electronic control units (vECUs), combining the virtual prototyping of Synopsys with Continental’s cloud-based development framework, Automotive Edge (CAEdge). The result is a digital twin that helps automotive manufacturers simplify software development and get their product to market faster.

Continental and DeepDrive develop wheel hub drive with integrated brake

In October 2023, Continental entered into a strategic partnership with Munich-based high-tech firm DeepDrive to develop core technologies for electric vehicles. As an initial milestone, the two companies are jointly developing a combined unit comprising drive system and brake components that will be mounted directly on a vehicle’s wheel. DeepDrive specializes in developing efficient electric motors and has extensive experience in large-scale automotive production. Continental, for its part, will contribute its technological know-how in brake systems and its expertise in industrializing innovative technologies.

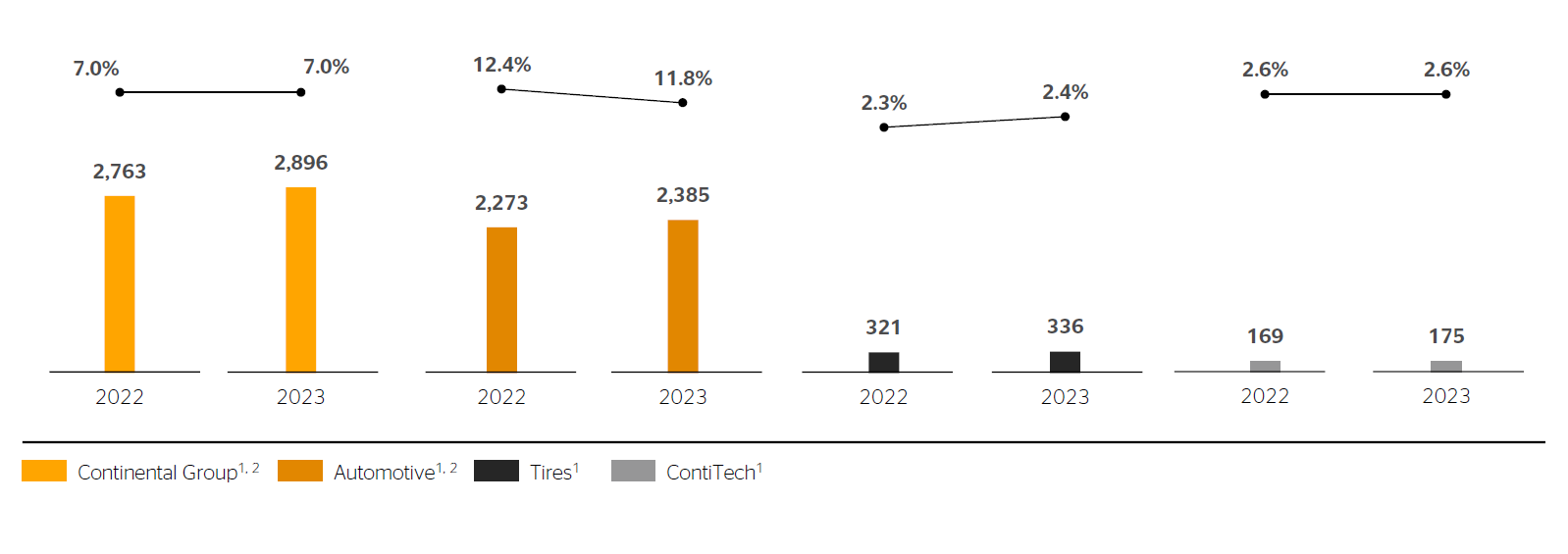

| Research and development expenses (net) | ||||

|---|---|---|---|---|

| 2023 | 2022 | |||

| € millions | % of sales | € millions | % of sales | |

| Automotive1,2 | 2,384.8 | 11.8 | 2,273.1 | 12.4 |

| Tires1 | 336.0 | 2.4 | 320.8 | 2.3 |

| ContiTech1 | 175.1 | 2.6 | 169.2 | 2.6 |

| Contract Manufacturing1 | 0.0 | 0.0 | 0.1 | 0.0 |

| Consolidation | 0.0 | - | -0.2 | - |

| Continental Group1,2 | 2,896.0 | 7.0 | 2,762.9 | 7.0 |

| Capitalization of research and development expenses | 17.6 | 24.4 | ||

| in % of research and development expenses1,2 | 0.6 | 0.9 | ||

| Depreciation on research and development expenses | 50.4 | 46.4 | ||

1 In the year under review, the presentation of income and expenses in connection with specific warranties, restructuring measures, severance payments, as well as impairment and reversal of impairment losses on intangible assets and property, plant and equipment was changed. They are now assigned to the relevant functional areas. The comparative period has been adjusted accordingly.

2 The assignment of income and expenses from certain business activities within the functional areas has been adjusted. The comparative period has been adjusted accordingly.

Continental starts production of its most sustainable tire to date and presents concept tire Conti CityPlus

In mid-2023, Continental started production of the UltraContact NXT, its most sustainable production tire to date, at its plant in Lousado, Portugal. Comprising up to 65% renewable, recycled and mass balance-certified materials, the tire combines a high share of sustainable materials with maximum safety and performance. All sizes have the highest possible rating (“A”) of the EU tire label in terms of rolling resistance, wet braking and exterior noise.

Continental unveiled its new Conti CityPlus concept tire at IAA Mobility in Munich in September 2023. The new tire technology reduces energy consumption by up to 10%, meaning lower CO2 emissions for cars with combustion engines and longer ranges for electric vehicles. This is achieved by optimizing tire behavior during stop-and-go urban traffic, which can extend a car’s range by up to 3%. This corresponds to a saving of 0.6 kWh per 100 kilometers for electric vehicles.

Continental named preferred tire partner of automotive manufacturers worldwide for electric and combustion engine vehicles

For more than a decade, Continental has been optimizing its tires to achieve lower rolling resistance, reduce rolling noise and increase service life – without compromising on safety. All passenger car tires of the Continental brand meet the requirements of electric vehicles, while at the same time they are able to sustainably reduce the emissions of combustion engine vehicles. This strategy is paying off, with the 10 highest-volume manufacturers of fully electric cars currently putting their trust in Continental’s technological expertise for their original equipment. Since last year, Chinese vehicle manufacturer BYD has been equipping its Seal electric sedan for the Chinese market with the Continental SportContact 7 and factory-fitting it with the Continental EcoContact 6 Q for global export.

Continental is the preferred tire partner of Mercedes-Benz in the Asia-Pacific region, comprising China, Australia, Malaysia and Indonesia.

On top of this, the existing partnership in India has been extended. Tires bearing the label “MO” (“Mercedes-Benz Original”) on the sidewall mean that they have been specially approved by Mercedes-Benz and meet strict requirements and standards. They are tailored specifically to the respective Mercedes-Benz vehicle model. Continental has fitted the automotive manufacturer’s entire portfolio with its tires, from the A-Class to the GLS-Class. In Europe and in the Asia-Pacific region, these include the SportContact, EcoContact and PremiumContact tire lines. In the Americas region, most notably in the USA and Canada, they also include the ProContact range.

Continental enables digital tire monitoring in real time

Since 2023, Continental has been offering an entry-level solution that streamlines the process for outfitting fleets with digital tire management. The new valve cap sensor supplies data on the condition of a vehicle’s tires, independent of the manufacturer, in a way that is straightforward, saves time and makes sure tires are running at their optimum performance. This results in greater fuel efficiency and longer tire life. In addition, the new sensor bolsters Continental’s “Lowest Overall Driving Costs“ (LODC) concept, through which Continental helps fleet operators manage their fleets more safely, sustainably and cost-efficiently.

The valve cap sensor is screwed directly onto a bus, truck or trailer’s tire valve, from where it measures the tire pressure in real time. The sensor is compatible with commercial-vehicle tires of all established manufacturers and autonomously links up to ContiConnect receiver units. Deviations from the target condition are recorded via the tire management platform of the same name and forwarded to users. A QR code on the valve cap sensor makes it easy to assign the sensor to the respective tire position, meaning there is no need for a special reader to determine the position; instead, this is done via a mobile device using the ContiConnect on-site app.

Continental also supplies relevant tire data in real time for the digital tire monitoring of truck trailers. New telematics units mean that tire data from truck trailers can continue to be received and delivered to the ContiConnect 2.0 tire management system even when parked, whereas before this was only possible while driving. Thanks to digital tire control, information on the trailer tires’ fill level and temperature can be consulted at any time. An integrated battery ensures daily measurement values can be sent for up to 28 days without an external power source. In this way, ContiConnect Live helps to reduce tire-related downtime. Tires can be maintained more proactively, keeping vehicles in roadworthy condition. On top of this, real-time status updates and warning signals increase efficiency and reduce labor and maintenance costs. ContiConnect Live additionally offers track-and-trace functionality using GPS data that shows the precise location of vehicles in the system at all times. Since July 2023, digital tire monitoring has also been available for free-standing truck trailers in multiple markets worldwide.

Continental to start testing tires for customers in a driving simulator

In November 2023, Continental commissioned its new driving simulator for tires, which effective immediately will be used for new developments and advancements, especially in the tire original equipment business. This was preceded by an intensive trial phase spanning approximately 12 months. Virtual tests save raw materials and shorten the development time for tires. The high-tech system, known as a driver-in-the-loop (DIL) simulator, calculates the exact driving dynamics parameters of the tires and the respective test vehicle. The simulator is highly flexible and can give Continental’s test drivers subjective driving impressions that are comparable with those gained from tire tests on a real test track.

The simulator can test tires for all vehicle and drive system variants, for both passenger cars and commercial vehicles, for electric and hybrid vehicles and for vehicles with combustion engines. The decisive advantage is that the tire parameters can be adjusted digitally at any time, meaning test drives can be repeated at short intervals and subjective driving impressions compared directly with one another. Equipped with a large motion platform (four meters long, five meters wide) and a maximum acceleration of 12 meters per second, test drivers experience all six degrees of freedom – just like in a real vehicle on a physical test track. These include longitudinal and lateral movements, the stroke movement and the yaw, pitch and roll of a vehicle.

Continental presents the vehicle interior of the future with its sustainable SPACE D design concept

With its new SPACE D concept, Continental gives a glimpse into the future of vehicle interior design, one that is shaped by electric mobility and autonomous driving. Continental is bringing the living room to the automotive interior, while placing the focus firmly on comfort, convenience and sustainability.

Many of the applied surface solutions have been engineered in line with the three defined pillars of sustainability – economy, ecology and social responsibility. Up close, the individual surfaces of SPACE D really catch the eye. With the functional dimension of surfaces gaining in importance, SPACE D employs a number of proven and patented technologies, such as heatable (for direct, fast and very precise heating), staynu (extremely resistant to dirt) and laif (breathable, comfortable, passive temperature control and acoustically effective).

Continental opens TechCenter for hydrogen technologies in Hamburg

In July 2023, Continental opened a new TechCenter for hydrogen technologies at its location in Hamburg-Harburg. Going forward, the ContiTech group sector will use the TechCenter as a collaborative platform for sharing and exchanging knowledge in this area, with a focus on promoting innovations and the transfer of existing technical solutions to new applications in hydrogen technology. The aim is to bring together experts from different fields and industries, whose task it will be to identify technical, regulatory and infrastructural challenges along the entire hydrogen value chain and develop overarching approaches and solutions that meet these needs.

R&D expenses (net) € millions |

R&D ratio %

1 In the year under review, the presentation of income and expenses in connection with specific warranties, restructuring measures, severance payments, as well as impairment and reversal of impairment losses on intangible assets and property, plant and equipment was changed. They are now assigned to the relevant functional areas. The comparative period has been adjusted accordingly.

2 The assignment of income and expenses from certain business activities within the functional areas has been adjusted. The comparative period has been adjusted accordingly.